With the acceleration of the pace of modern life, instant noodles have become the preferred fast food for more and more people around the world because of its convenient, fast and delicious characteristics. This has also promoted the development of the instant noodle production industry. However, the production of instant noodles is not simple, a complete fried instant noodles production line consists of many equipment. How to design an instant noodle production line, as a long-term engaged in the food machinery industry staff, I organize the main equipment of the instant noodle production line as follows, I hope to help you.

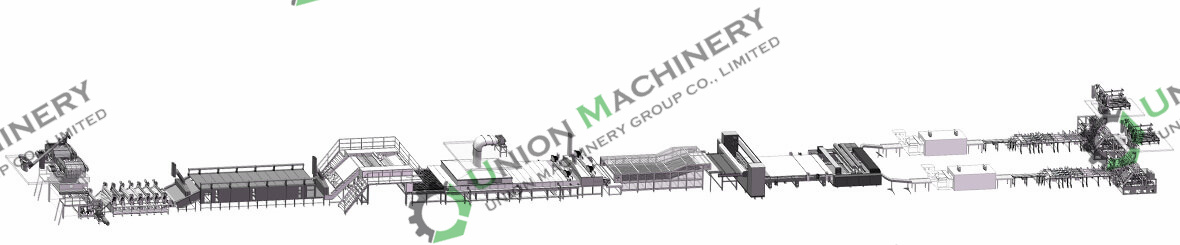

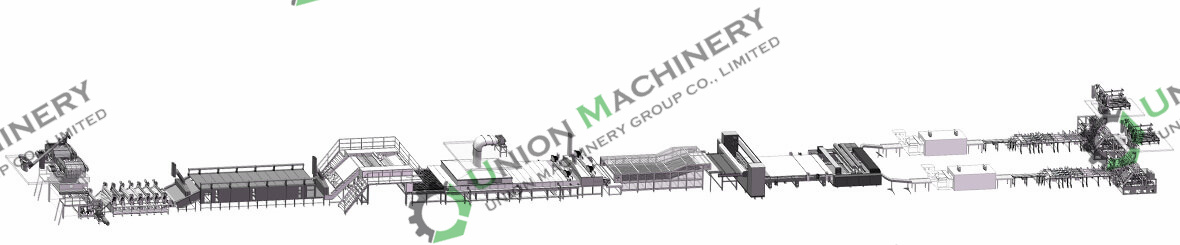

First of all, let's take a look at the instant noodle production line as a whole, which generally includes the flour supply link, the dough mixing link, the noodle awakening link, the pressing surface cutting link, the steaming link, the cutting and arranging link, the frying link, the cooling link, the sauce link, the quality control link and the packaging link.

1. Flour supply link

The powder is fed directly by sifting machine and screw conveyor or by centralized automatic feeding. The flour is quickly sent to the flour mixer by positive pressure. Full automatic operation, effectively reduce labor intensity, full monitoring, accurate quantitative, to ensure food safety and reliability. The main equipment is powder feeding machine.

2. Dough mixing link

It is to mix flour and water evenly for a certain time to form a wet dough with certain processing properties. The main equipment is a brine mixing system and a flour mixer.

Basic principle: When flour is evenly mixed with water, the gluten and glutenin in the flour absorb water and expand, surrounded by a network of wet gluten. When a certain gluten network is formed, stop fast beating so as not to interrupt the formed network, and start slow beating to further expand and extend the gluten, so that the dough formed has good processing properties.

3. Noodle awakening link

Aging is also called wakes up the dough, a process that further improves the processing properties of the dough with the passage of time. The main equipment is waking machine/curing machine.

Main functions:

4. Pressing surface cutting link

The matured dough is continuously rolled by a multi-channel press roller to meet the requirements of a certain thickness of the surface, and then through a pair of knife rollers, is cut into strips, through the molding machine transmitted to the molding mesh belt to form a wave shape, that is, the unique shape of instant noodles. The main equipment is compound press and cutting machine.

Main functions:

5. Steamed noodles link

The noodles are heated and steamed through steam at a certain time and temperature. It's actually a process of starch gelatinization. Gelatinization is a process in which starch particles absorb water and dissolve at the appropriate temperature, forming a paste, and starch molecules change from a regular arrangement to a chaotic arrangement, so that enzyme molecules are easy to enter between molecules and easy to digest and absorb. The main equipment is noodle steamer.

6. Cutting and arranging link

Through the quantitative cutting equipment, the corrugated surface strip from the steaming machine is cut off according to a certain length, and the cut surface strip is folded in half to arrange output, and after cutting into the box, it is blown and shaped and then enters the frying stage. You can make different sizes of square or round flatbread. The main equipment is quantitative cutting machine and trimming machine.

7. Frying link

It is to put the quantitative cut noodles into the frying box, through the high-temperature oil tank, the water in the noodles quickly vaporized, the noodles formed porous structure, starch further gelatinization, improve product quality, while conducive to storage. The main equipment is frying machine.

Main functions:

8. Cooling link

Fresh out of the fryer, the pastry temperature is too high, will burn the packaging film and soup, so several sets of fans are often used to cool it to room temperature for packaging. The main equipment is air cooling machine.

9. Sauce link

Mix all kinds of spices according to a certain proportion to make seasoning sauce. The main equipment includes sauce stir-frying machine, powder and vegetable bag mixing and packaging machine, and parcel delivery machine.

10. Quality control link

Products are inspected by weighing and foreign body screening machines to ensure product quality. The main equipment is foreign body screening machine or X-ray machine.

.jpg)

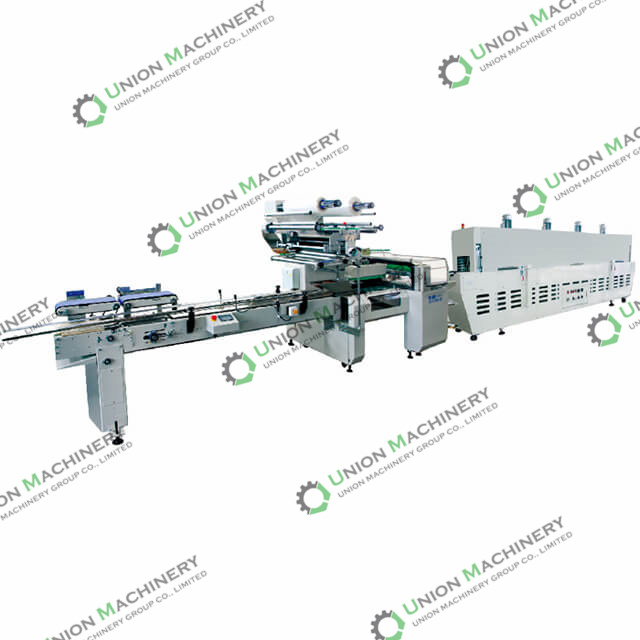

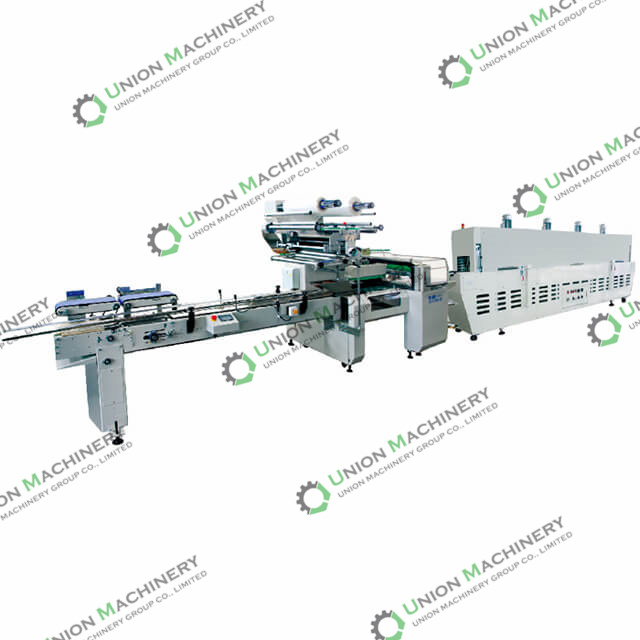

11. Packaging link

The fried noodles and sauce are packed into packaging bags, which are sealed/capped by sealing equipment. Finally, the products are packed and boxed by packing equipment. The main equipment is sealing machine, capping machine, packing machine.

The above are the main components of the instant noodle production line, according to these contents, I believe you will be able to design a perfect fried instant noodle production line.

Our company has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: https://www.hnunmachinery.com/product/;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at jodie@unmachinery.com or info@unmachinery.com

The following are other knowledge related to instant noodle production that I have summarized based on long-term work experience, for your reference. I hope you don't take the wrong path.

1.What are the factors that affect the dough mixing effect in the production of instant noodles?

2.What are the factors affecting the awakening effect of instant noodle production?

3.What are the factors affecting the Calendering effect of instant noodles production?

4.What are the factors affecting the cutting and shaping of instant noodles production?

5.What are the factors affecting the frying effect of instant noodles production?

6.What are the factors affecting the steaming effect of instant noodles production?

7.Precautions for operating rolling equipment on instant noodle production line

8.How to determine whether the rolling effect of the rolling machine is qualified?

9.How should the rolling machine be adjusted when working to ensure product quality?

10.How to solve common faults of steaming machine?

11.How to do if the steamed noodles are half-cooked?

First of all, let's take a look at the instant noodle production line as a whole, which generally includes the flour supply link, the dough mixing link, the noodle awakening link, the pressing surface cutting link, the steaming link, the cutting and arranging link, the frying link, the cooling link, the sauce link, the quality control link and the packaging link.

1. Flour supply link

The powder is fed directly by sifting machine and screw conveyor or by centralized automatic feeding. The flour is quickly sent to the flour mixer by positive pressure. Full automatic operation, effectively reduce labor intensity, full monitoring, accurate quantitative, to ensure food safety and reliability. The main equipment is powder feeding machine.

2. Dough mixing link

It is to mix flour and water evenly for a certain time to form a wet dough with certain processing properties. The main equipment is a brine mixing system and a flour mixer.

Basic principle: When flour is evenly mixed with water, the gluten and glutenin in the flour absorb water and expand, surrounded by a network of wet gluten. When a certain gluten network is formed, stop fast beating so as not to interrupt the formed network, and start slow beating to further expand and extend the gluten, so that the dough formed has good processing properties.

3. Noodle awakening link

Aging is also called wakes up the dough, a process that further improves the processing properties of the dough with the passage of time. The main equipment is waking machine/curing machine.

Main functions:

- Makes the water further penetrate into the interior of the protein colloidal particles, fully absorb water and expand, and further form the gluten network, which is actually the continuation of the kneading process.

- Eliminate dough internal structure stability.

- The water between protein and starch can be automatically regulated and homogenized.

- Play a uniform feeding role for the composite calender.

4. Pressing surface cutting link

The matured dough is continuously rolled by a multi-channel press roller to meet the requirements of a certain thickness of the surface, and then through a pair of knife rollers, is cut into strips, through the molding machine transmitted to the molding mesh belt to form a wave shape, that is, the unique shape of instant noodles. The main equipment is compound press and cutting machine.

Main functions:

- Press the loose dough into fine, thin pieces that meet the requirements.

- Further promotes the fineness of gluten network organization, and makes the fine network organization evenly distributed in the flour sheet to surround the starch particles, so that the flour sheet has a certain toughness and strength.

- Cut dough into strips and form waves.

5. Steamed noodles link

The noodles are heated and steamed through steam at a certain time and temperature. It's actually a process of starch gelatinization. Gelatinization is a process in which starch particles absorb water and dissolve at the appropriate temperature, forming a paste, and starch molecules change from a regular arrangement to a chaotic arrangement, so that enzyme molecules are easy to enter between molecules and easy to digest and absorb. The main equipment is noodle steamer.

6. Cutting and arranging link

Through the quantitative cutting equipment, the corrugated surface strip from the steaming machine is cut off according to a certain length, and the cut surface strip is folded in half to arrange output, and after cutting into the box, it is blown and shaped and then enters the frying stage. You can make different sizes of square or round flatbread. The main equipment is quantitative cutting machine and trimming machine.

7. Frying link

It is to put the quantitative cut noodles into the frying box, through the high-temperature oil tank, the water in the noodles quickly vaporized, the noodles formed porous structure, starch further gelatinization, improve product quality, while conducive to storage. The main equipment is frying machine.

Main functions:

- To gelatinize the starch completely.

- Dehydration.

- Fix the shape.

8. Cooling link

Fresh out of the fryer, the pastry temperature is too high, will burn the packaging film and soup, so several sets of fans are often used to cool it to room temperature for packaging. The main equipment is air cooling machine.

9. Sauce link

Mix all kinds of spices according to a certain proportion to make seasoning sauce. The main equipment includes sauce stir-frying machine, powder and vegetable bag mixing and packaging machine, and parcel delivery machine.

10. Quality control link

Products are inspected by weighing and foreign body screening machines to ensure product quality. The main equipment is foreign body screening machine or X-ray machine.

.jpg)

11. Packaging link

The fried noodles and sauce are packed into packaging bags, which are sealed/capped by sealing equipment. Finally, the products are packed and boxed by packing equipment. The main equipment is sealing machine, capping machine, packing machine.

The above are the main components of the instant noodle production line, according to these contents, I believe you will be able to design a perfect fried instant noodle production line.

Our company has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: https://www.hnunmachinery.com/product/;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at jodie@unmachinery.com or info@unmachinery.com

The following are other knowledge related to instant noodle production that I have summarized based on long-term work experience, for your reference. I hope you don't take the wrong path.

1.What are the factors that affect the dough mixing effect in the production of instant noodles?

2.What are the factors affecting the awakening effect of instant noodle production?

3.What are the factors affecting the Calendering effect of instant noodles production?

4.What are the factors affecting the cutting and shaping of instant noodles production?

5.What are the factors affecting the frying effect of instant noodles production?

6.What are the factors affecting the steaming effect of instant noodles production?

7.Precautions for operating rolling equipment on instant noodle production line

8.How to determine whether the rolling effect of the rolling machine is qualified?

9.How should the rolling machine be adjusted when working to ensure product quality?

10.How to solve common faults of steaming machine?

11.How to do if the steamed noodles are half-cooked?