Table of Contents

· 1.Water Sourcing and Treatment: Ensuring Purity from the Start

· 2.Bottle Manufacturing or Preparation: Creating the Containers

· 3.Rinsing and Cleaning: Preparing Bottles for Filling

· 4.Filling: Dispensing Purified Water into Bottles

· 5.Capping and Sealing: Ensuring a Secure and Tamper-Evident Seal

· 6.Labeling and Packaging: Branding and Preparing for Distribution

· 7.Quality Control and Safety Checks: Ensuring Every Bottle is Perfect

· 8.Conclusion: A Seamless and Hygienic Filling Process

Have you ever wondered how every bottle of purified water on the store shelf gets filled with clean, safe water? It’s a complex process that involves multiple stages of treatment, precision engineering, and strict quality control. In this guide, I will walk you through the entire PET bottle filling process step by step. By the end, you’ll understand exactly how PET bottles of purified water are filled and what makes this process so efficient and reliable.

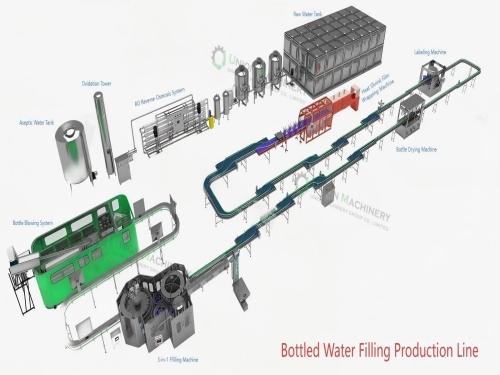

PET bottles of purified water are filled using an automated production line that integrates several key stages. First, the water undergoes rigorous treatment and purification to meet safety standards. Next, either pre-made PET bottles are produced on-site or delivered, and they are thoroughly rinsed to ensure cleanliness. The purified water is then filled into the bottles using high-precision filling machines, after which the bottles are capped and sealed. Finally, the bottles are labeled with product information and packaged for distribution. This entire process is designed to be efficient, hygienic, and consistent, ensuring that every bottle of water you buy is safe and of high quality.

Water Sourcing and Treatment: Ensuring Purity from the Start

The journey of bottled water begins long before it reaches the bottling line. It starts with sourcing the water and then treating it to meet stringent purity standards. Without proper treatment, bottled water would not be safe for consumption. This initial stage is critical because it lays the foundation for the quality and safety of the final product.Water treatment involves multiple steps to remove impurities and contaminants. Common methods include filtration (to remove particles and sediment), activated carbon filtration (to remove chlorine and odors), reverse osmosis (to eliminate dissolved solids), and disinfection using UV light or ozone (to kill bacteria and viruses). These processes ensure that the water is pure and meets regulatory standards for drinking water. For example, reverse osmosis systems can remove up to 99% of dissolved salts, minerals, and other impurities, resulting in water that is safe and has a clean taste. By the end of the treatment stage, the water is crystal clear, free of harmful contaminants, and ready for bottling.

Bottle Manufacturing or Preparation: Creating the Containers

Once the water is purified, the next step is to ensure the bottles themselves are ready. PET bottles are the standard for water packaging due to their lightweight, shatter-resistant, and recyclable properties. But how do these bottles get made, and what happens to them before filling? The preparation of bottles is a crucial stage that directly impacts the filling process and the quality of the final product.In modern bottling plants, PET bottles are often produced on-site using a process called stretch blow molding. This involves heating small PET preforms (which look like test tubes with threads) and then using high-pressure air to stretch and mold them into the desired bottle shape. On-site bottle production offers advantages like cost savings and customization, as manufacturers can create bottles tailored to their brand. If pre-made bottles are used instead, they are carefully inspected for defects and cleanliness before being fed into the line. Regardless of the source, every bottle must be clean and structurally sound before filling. This stage may also include quality checks to ensure uniform wall thickness and proper neck finish, which are important for sealing and preventing leaks.

Rinsing and Cleaning: Preparing Bottles for Filling

Even though PET bottles are manufactured in a controlled environment, they still need to be thoroughly cleaned before filling. Any dust, debris, or residual particles inside the bottle could contaminate the water. That’s why every bottle undergoes a rinsing process to ensure it is pristine and ready for the purified water. This step is all about maintaining hygiene and preventing any foreign particles from ending up in the final product.The rinsing process is typically automated and highly efficient. Bottles are usually inverted and sprayed with purified water or filtered air to wash out any internal contaminants. This ensures that the inside of each bottle is as clean as the water that will soon fill it. In some advanced systems, bottles may even pass under UV sterilizers during rinsing for an extra layer of disinfection. By the end of this stage, every bottle is sparkling clean and free of any particles that could compromise the water’s purity. This rigorous cleaning step is a key part of why bottled water remains safe and consistent, even after long storage periods.

Filling: Dispensing Purified Water into Bottles

With clean bottles in place, it’s time for the main event: filling the bottles with purified water. This is the heart of the bottling process, where precision and speed are paramount. The goal is to fill each bottle with the exact amount of water without spillage or contamination. Modern bottling lines use advanced filling machines to achieve this with remarkable accuracy and efficiency.Filling is usually done by automated rotary or linear filling machines that can handle thousands of bottles per hour. These machines are designed to maintain a sterile environment and often operate in a clean room or with enclosed filling chambers to prevent airborne contaminants. For still water, a gravity filling system is commonly used, where water flows from a tank into each bottle by gravity, ensuring a gentle fill that preserves the water’s clarity and taste. Carbonated water, on the other hand, requires a counter-pressure filling system to maintain the fizz. The filling machines are calibrated to dispense the precise volume (for example, 500 ml or 1 liter) into each bottle, and they include sensors to stop the flow once the correct level is reached. This stage is critical for product consistency – too little water and the bottle is underfilled; too much and it can cause spillage or affect sealing. By the end of the filling step, every bottle contains the exact amount of purified water, ready for the next stage of capping.

Capping and Sealing: Ensuring a Secure and Tamper-Evident Seal

After the bottles are filled, they must be sealed immediately to lock in freshness and prevent any contamination. The capping and sealing stage is where the bottles receive their caps or lids, creating an airtight and tamper-evident seal. This step is crucial for maintaining the water’s quality and safety during storage and transportation. A properly sealed bottle not only keeps the water fresh but also gives consumers confidence that the product has not been opened or altered.In the bottling line, filled bottles move to a capping machine where caps are applied and tightened. The type of cap can vary – screw caps are common for PET water bottles, but some products may use press-on lids or other closures. The capping machine ensures each cap is applied with the correct torque (tightness) to create a perfect seal. Many systems include sensors that detect if a cap is missing or not properly sealed, and such bottles are automatically rejected. After capping, some lines may also apply a tamper-evident band or shrink sleeve over the cap and neck of the bottle for added security. By the end of this stage, every bottle is securely sealed and ready for labeling. The sealed bottles are now leak-proof and airtight, which is essential for preserving the water’s purity and extending its shelf life.

Labeling and Packaging: Branding and Preparing for Distribution

With the bottles filled and sealed, the next step is to give them their identity and prepare them for the outside world. Labeling and packaging are the final stages of the bottling process, where bottles receive their branding and are grouped for shipping. This stage is not just about aesthetics – it’s also about providing important information to consumers and ensuring the product can be transported safely and efficiently.Labeling is typically done by high-speed labeling machines that apply wrap-around labels or sleeve labels to each bottle. These labels carry essential information such as the brand name, logo, nutritional facts, production date, and expiration date. Modern labeling equipment can apply labels with precision and consistency, even at high line speeds. After labeling, the bottles are often grouped into packs or cartons. This can involve placing them into cardboard trays, shrink-wrapping them in plastic film, or putting them into larger crates. The packaging step ensures that the bottles are protected during handling and transportation. Finally, the packaged bottles are moved to a palletizing area where they are stacked onto pallets, shrink-wrapped, and made ready for shipment to distributors. By the end of this stage, the bottled water is fully packaged and labeled, ready to be sent to stores and consumers.

Quality Control and Safety Checks: Ensuring Every Bottle is Perfect

Throughout the entire filling process, quality control (QC) is an ongoing and critical component. From the water source to the final packaged product, numerous checks are in place to ensure that every bottle of water meets the highest standards of safety and quality. QC is not just a single step – it’s a series of checks and balances that happen at each stage to catch any issues early and maintain consistency.Quality control measures include testing the water at various points (source water, water after treatment, and final product) to ensure it remains pure and free of contaminants. Bottles are also inspected for defects – for example, vision systems can check for misshapen bottles, improper sealing, or labeling errors. Any bottle that fails these checks is automatically removed from the line. Additionally, the production environment itself is monitored; clean room conditions and regular sanitation of equipment help prevent microbial contamination. Many bottling plants also adhere to international standards like HACCP (Hazard Analysis and Critical Control Points) and ISO 22000 to systematically manage food safety. By implementing rigorous QC protocols, manufacturers can guarantee that each bottle leaving the plant is safe, correctly filled, and properly sealed. This commitment to quality is what gives consumers confidence in the bottled water they purchase.

Conclusion: A Seamless and Hygienic Filling Process

In conclusion, filling PET bottles with purified water is a highly orchestrated process that combines advanced technology with strict quality control. It begins with treating water to ensure it’s pure and safe, followed by preparing or manufacturing clean PET bottles. The bottles are then rinsed, filled with precision, capped to create an airtight seal, and finally labeled and packaged for distribution. Each step is designed to be efficient, hygienic, and consistent, leveraging automation to minimize human error and contamination. The result is a product that is uniform in quality and safety – every bottle of water you buy has undergone this journey to reach you. By understanding how PET bottles of purified water are filled, we can appreciate the engineering and care that go into producing such a simple yet essential product. This process not only meets the demands of large-scale production but also upholds the highest standards of quality, ensuring that consumers around the world can enjoy clean, safe drinking water at their convenience.

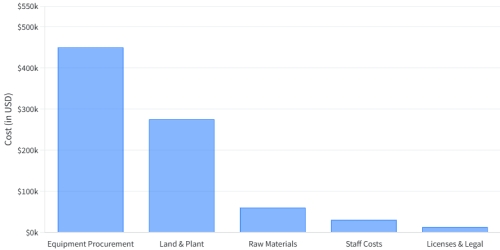

Figure 1: Estimated Initial Investment Cost Breakdown for a Small to Medium-Sized Bottled Water Plant

Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: Bottled Water Filling Machine;More video information see view: Bottled Water Production Line 、PET Bottled Water Production Line. Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to Bottled Water Filling Production Line that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.How to Design a PET Bottled Water Production Line?

2.What Are the Advantages of 3-in-1 Bottled Water Filling Machines?

3.What Are The Common Faults of 3-in-1 Bottled Water Filling Machine?