Effective analysis requires weighing both upfront costs and long-term operational savings. You must examine key price components, track lifetime expenses, compare configurations, build custom ROI models, and align choices with your production goals.

Smart buyers don't just look at price tags. They dig into true cost drivers. Below we dissect critical factors every dairy processor should know.

1.What Are The Components of The Price for Canned Milk Powder Equipment?

Ever wonder why sticker prices vary wildly? Real costs hide beyond the base model.

Milk powder canning equipment costs include machine purchase price, installation fees, training programs, spare parts inventory, and testing materials (sealants/sensors).

| Upfront Cost Components | Impact Range | |

| Equipment Core | Filling nozzles, sealing heads | 40-65% of total cost |

| Automation Level | Manual vs servo-driven systems | +15-30% price variance |

| Material Grade | 316L stainless steel vs standard | +8-25% premium |

| Installation | Calibration + site prep | 5-15% |

| Training | Operator certification | 2-8% |

Three hidden factors dramatically alter real pricing.

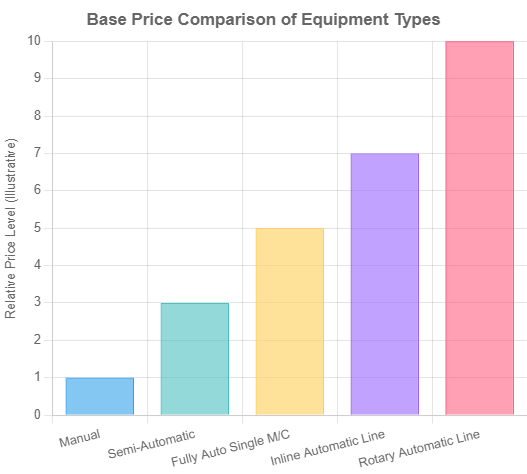

First, automation systems like servo-driven fillers boost precision but add 15-30% to base prices.

Second, material choices increase durability. Food-grade 316L stainless steel resists corrosion from milk proteins though costing 8-25% more.

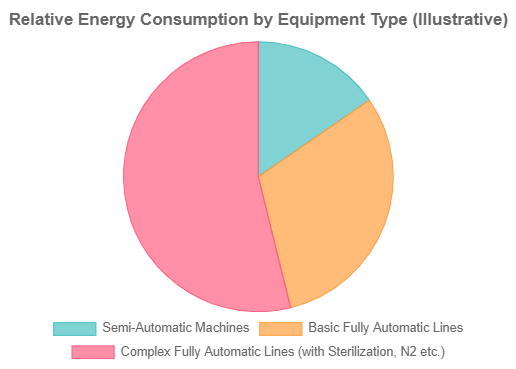

Third, specialized components matter. Nitrogen flushing units that extend shelf life may seem optional but prevent spoilage losses exceeding $10,000 monthly.

Buyers should request breakdowns showing alloy grades. At Union Machinery, we provide transparent quotes with itemized consumable costs. Our Turkish dairy client saved 17% by matching steel grades to powder acidity levels.

2.What Is The Long-term Cost of Operating Milk Powder Canning Equipment?

Low purchase price fools many buyers. Real costs emerge during daily runs.

Long-term costs include power consumption ($18-$35/hr), maintenance contracts (6-12% of original price/year), spare parts, labor inefficiencies, and waste from seal failures ($300+/hour downtime).

| Operational Cost Drivers | Prevention Strategies | |

| Energy Use | Motor efficiency grades | Servo-driven systems cut usage 30% |

| Maintenance | Seal wear-and-tear | Modular spares reduce downtime 65% |

| Waste | Overfilling errors | Automated feedback loops |

| Labor | Manual adjustments | Smart HMI interfaces |

Long-term expenses reveal true equipment value.

Power consumption often gets overlooked - traditional machines use $35/hour during peak loads, while modern versions like our UNM series consume just $18. Maintenance frequently costs 12% of original investment yearly.

Seals fail every 500 operating hours, causing $300/hour shutdowns plus product loss. We solve this with self-adjusting gaskets in Argentinian milk plants that reduced interventions by 76%.

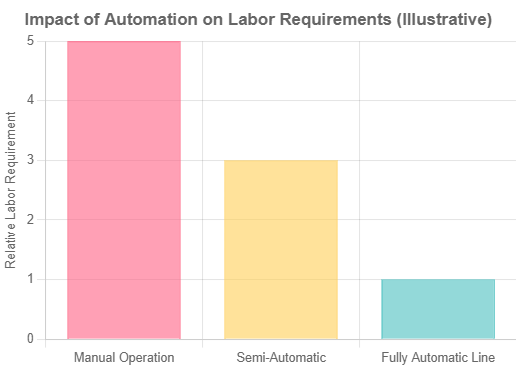

Labor inefficiencies create another leak. Manual adjustments require 3 operators/shift at $21/hour each versus automated systems needing one.

Our clients report payback in under 10 months through waste reduction alone.

3.Which Configurations Provide The Best Cost-effectiveness?

Does "fully loaded" mean overpaying? Smart configurations balance performance with budget.

Mid-tier automation with modular scalability offers peak cost-effectiveness. Prioritize servo-controlled filling valves, optional CIP systems, and data-logging HMI screens over cosmetic upgrades.

| Essential Configurations | Budget Alternatives | |

| Cleaning System | Full CIP auto-clean (+$7K) | Manual flush ports |

| Accuracy | ±0.5% servo fillers | ±1.5% pneumatic |

| Monitoring | Cloud-connected HMI | Basic LED alarms |

| Hygiene | IP69K rating |

Standard housing |

Balancing features and price requires understanding operational contexts. Small farms making seasonal products benefit from basic pneumatic fillers (±1.5% accuracy), while large plants need ±0.5% servo precision to control $100K/month powder loss. CIP cleaning systems add $7k upfront but save $150/shift in sanitation labor.

During Canadian facility upgrades, we proved modular designs are key. Install entry-level machines with expansion slots for future humidity sensors. Avoid useless stainless steel panels where powder doesn't make contact. Our data shows facilities making 8+ product variants need HMIs tracking blend recipes. Single-product factories skip this.

4.How To Establish A Return On Investment Model for This Device?

Are vague projections risking your budget? Build ROI models that mirror reality.

Calculate ROI by: (Annual savings from efficiency gains + Reduced waste value) - (Annual maintenance + Depreciation). Base figures on measurable KPIs like fill-speed variance (±0.8% max).

| ROI Variable | Measurement Method | Sample Data |

| Efficiency Gain |

Bottles/min x uptime % |

650% throughput rise seen in dairy cases |

|

Waste Reduction |

Seal failure rate tracking |

$18-45K/yr savings |

|

Maintenance |

Service contract terms |

12% of capex average |

|

Depreciation |

5-7 year equipment lifespan |

15-20% annual |

Construct bulletproof ROI models using real inputs.

First, measure current losses. A Mexican powder plant tracked $300/day from overfilling before our intervention.

Second, compare throughputs. Automated filling lines like the UNM-200 series achieve 140 cans/minute versus manual 22 cans.

Third, incorporate downtime costs. Every 1% reduction in unplanned stops saves $5,200 annually in medium plants.

Fourth, model payback periods. Our Philippine clients recovered investments in 11-16 months through efficiency upgrades. We build custom calculators that account for local power rates ($0.08-$0.22/kWh) and labor costs. Remember depreciation - equipment loses 20% value yearly.

5.How To Make The Best Investment Decision for Your Business?

Ready to buy but overwhelmed by choices? Align equipment with precise operational needs.

Assess daily production volumes (+/-15% growth projections), required speed tolerance (±0.3-1.5%), maintenance skill levels, and facility space constraints before choosing machinery.

| Decision Factors | Due Diligence Actions | |

| Scalability |

Check frame upgrade capacity |

Measure aisle widths |

|

Skill Requirements |

Interview maintenance team |

Require vendor training certs |

|

Powder Variants |

Count formulation changes |

Test material funnel angles |

|

Support |

Verify spare parts storage |

Inventory turnaround time |

Transform your decision process from guessing to data-driven. Start with volume audit gaps. Plants targeting 6.2% yearly growth (industry forecast) need modular machines accepting speed boosters.

Match complexity to worker skills. Basic facilities benefit from our mechanical manual fillers rather than sensor-laden premium units. Always test your powder flow in vendor demo labs. High-fat blends jam equipment not designed for their viscosity.

Before signing, validate after-sales support responsiveness. Our standard service includes same-day video troubleshooting and 24/7 technical assistance, spare parts availability.

Conclusion

Selecting milk powder canning equipment demands analyzing both purchase costs and lifetime value. Focus on configurations matching production realities and build precise ROI models.

Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: Milk Powder Filling Production Line;Our expertise and advantages will bring you more opportunities and development space.For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to milk powder packaging line that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.How to Build an Efficient Canned Milk Powder Packaging Line?

2.How to Select the Right Infant Formula Packaging Equipment for Global Markets?

3.What Are Common Problems with Powder Filling Machines and How to Fix Them?

4.What Are the Common Types of Infant Formula Packaging Machines?