You know that packaging infant formula is a high-stakes game. You need absolute precision, top-notch hygiene, and reliable machinery to meet demanding production schedules. Choosing the wrong equipment can lead to costly contamination issues, product waste, and damage to your brand's reputation, not to mention failing to meet stringent safety standards. But what if you could confidently select the perfect packaging solution tailored to your specific needs, ensuring product integrity and operational efficiency?

Common infant formula packaging machines include auger fillers, vertical form-fill-seal (VFFS) machines, pre-made pouch packaging machines, and complete can filling and sealing lines. These machines are generally classified based on their level of automation (manual, semi-automatic, fully automatic), the filling mechanism they use (like augers for powders), their design configuration (inline or rotary), and the final packaging format they produce (such as cans, pouches, or sachets).

How Are Infant Formula Packaging Machines Classified and What Standards Apply?

Trying to understand the different classifications and the web of standards for infant formula packaging machinery can feel overwhelming. If you misinterpret these, you might invest in equipment that doesn't comply with critical food safety regulations, leading to serious legal trouble or your products being rejected by international markets. Imagine, instead, having a clear framework that helps you choose compliant, efficient machinery every time.

We find that infant formula packaging machines are primarily classified by their automation level (manual, semi-automatic, or fully automatic), their filling mechanism (auger fillers are very common for powders like infant formula), their overall design (such as inline, rotary, or multi-head configurations), and the type of package they handle (like cans, flexible pouches, or stick packs). Key standards you must consider include Good Manufacturing Practices (GMP), Hazard Analysis and Critical Control Points (HACCP) systems, and specific regulations like the FDA's 21 CFR Part 106 for infant formula. (Source: Levapack) (Source: U.S. FDA)

| Degree of Automation | Applicable Scale | Advantages | Disadvantages | Typical Application |

| Manual | Small-scale, research and development, customization | Low investment, high flexibility | Low production capacity and high labor intensity | Small-batch, specially formulated milk powder |

| Semi-automatic | medium-scale | Increased production capacity, easy operation | Still requires manual intervention and has limited efficiency. | Small and medium-scale enterprises, growth-stage enterprises |

| Fully Automatic | Large-scale | High efficiency, good stability, and reduced labor costs | High investment, complex maintenance | Large dairy enterprises, infant formula milk powder |

Let's break this down a bit. The level of automation you need will depend on your production volume. Small-scale operations might start with semi-automatic machines, but large enterprises handling infant formula will almost certainly require fully automatic lines for consistency and speed. The filling mechanism is crucial for powders; auger fillers, which use a screw to dispense product, are favored for their accuracy with products like infant formula. (Source: Hnunmachinery)

Regarding standards, GMP guidelines are fundamental for ensuring product quality and safety throughout the manufacturing process. HACCP is a systematic approach to identifying, evaluating, and controlling food safety hazards. For infant formula, which is a sensitive product for a vulnerable population, adherence to these standards is non-negotiable. Many countries also have their own specific regulations that build upon these international principles. For example, Health Canada provides guidance on GMP for infant formula, encouraging HACCP application. (Source: Health Canada)

What Are Auger Filling Machines for Infant Formula: Pros, Cons, and Applications?

You need to dose infant formula with extreme precision because even small variations can impact nutritional value and regulatory compliance. If your filling isn't accurate, you could be facing product recalls, financial losses from overfilling, or, worse, health concerns for infants. What if there was a reliable filling technology designed for such sensitive powders, ensuring each package meets exact specifications?

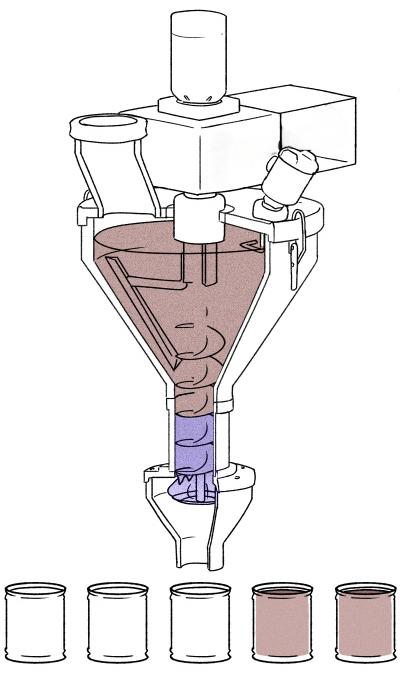

I can tell you that auger filling machines are a top choice for packaging infant formula due to their high accuracy in dispensing powders. They work by using a precisely machined screw (the auger) that rotates within a funnel to dispense a measured amount of powder into containers. Their main advantages include versatility with different powder characteristics and fill volumes, and the ability to integrate into fully automated lines.

Pros: Auger fillers, especially those with servo motor controls, offer excellent fill accuracy, often within ±1%. They can handle a range of powder types, from free-flowing to some non-free-flowing ones. They are suitable for various packaging types, including cans, jars, and pouches. Many modern machines are built with stainless steel for hygiene and ease of cleaning.

Cons: High-precision auger fillers can represent a significant initial investment. For some very delicate powders, the auger's mechanical action could potentially cause some degradation if not designed carefully. Thorough cleaning is essential to maintain hygiene standards for infant formula, and this can sometimes be time-consuming depending on the machine's design.

Applications: Auger fillers are widely used in the food and pharmaceutical industries. For infant formula, they are the go-to solution for filling cans and pouches accurately. They are also used for other powdered products like milk powder, protein powders, spices, and pharmaceutical powders.

Vertical Form-Fill-Seal (VFFS) Machines for Infant Formula: When Are They a Good Fit?

Perhaps your business needs to package infant formula into pouches efficiently and at high volumes, but you're worried about material costs and production speed. Using pre-made pouches can be expensive for large runs, and manual or semi-automatic processes just can't keep up. Imagine a machine that creates, fills, and seals pouches from a single roll of film, streamlining your operation and cutting costs.

I believe Vertical Form-Fill-Seal (VFFS) machines are an excellent fit when you need high-speed, cost-effective pouch packaging for infant formula, especially for long production runs of a consistent bag type. These machines form the bag from a flat roll of packaging film, fill it with product (often using an integrated auger filler), and then seal it, all in a continuous vertical motion.

Pros: VFFS machines offer high packaging speeds, making them ideal for large-scale production. (Source: Hnunmachinery) They are generally more cost-effective in terms of packaging material because they use film rolls rather than more expensive pre-made pouches. They can produce various bag styles like pillow bags and gusseted bags. Modern VFFS machines can be integrated with features like gas flushing for modified atmosphere packaging (MAP) to extend shelf life.

Cons: VFFS machines are typically less flexible when it comes to frequent changes in bag size or style; such changes often require significant downtime and change parts. The initial investment for a robust VFFS machine suitable for infant formula can be substantial.

Applications: These machines are widely used for packaging a variety of powdered products, including infant formula, milk powder, coffee powder, and spices, into different types of pouches and sachets for retail and bulk distribution. They are particularly suited for companies with high production volumes and limited product/pouch variety.

Pre-made Pouch Packaging Machines: Are They Better for Flexibility in Infant Formula Packaging?

Your market might demand a variety of pouch styles for infant formula – stand-up pouches, pouches with zippers, or unique shapes – and you need to switch between them quickly. A VFFS machine could be too rigid for this, leading to missed opportunities or the need for multiple machines. What if you could have a machine that offers the adaptability to handle diverse pre-formed pouches with ease?

In my experience, pre-made pouch packaging machines offer superior flexibility if your infant formula packaging strategy involves diverse pouch types, sizes, or features, and you require frequent changeovers. These machines are designed to pick, open, fill (again, often with an auger filler), and seal already manufactured pouches.

Pros: The biggest advantage is flexibility. You can easily switch between different pouch styles, including stand-up pouches, flat pouches, and those with reclosable features like zippers or spouts, which are increasingly popular for consumer convenience. Pre-made pouches often offer a more premium look and feel, which can enhance brand perception. Changeover times are generally quicker than on VFFS machines.

Cons: The cost per bag is typically higher with pre-made pouches compared to using roll-stock film on a VFFS machine. While automated, the overall speed might be lower than dedicated high-speed VFFS lines, especially for very large production volumes of a single product. The initial investment for the machine itself can also be significant.

Applications: These machines are ideal for companies producing infant formula in a variety of SKUs with different pouch requirements. They are also well-suited for contract packagers or brands that prioritize premium packaging aesthetics and functionality, such as stand-up pouches with zippers for multi-serve infant formula products. Some rotary powder packing machines use this principle.

Can Filling and Sealing Lines for Infant Formula: The Gold Standard for Preservation?

When it comes to infant formula, ensuring maximum product integrity and a long, stable shelf life is absolutely critical. You worry that flexible packaging might not offer enough protection against oxygen or moisture, potentially compromising the product. Imagine a packaging system renowned for its robustness and ability to preserve sensitive powders in optimal condition for extended periods.

I often see complete can filling and sealing lines considered the gold standard for infant formula packaging, primarily because they offer excellent product protection and facilitate a long shelf life through hermetic sealing and modified atmosphere packaging (MAP). These lines typically integrate multiple stages, including can cleaning, precise auger filling, gas flushing (usually with nitrogen), and sealing.

Pros: Metal cans provide a superior barrier against oxygen, moisture, light, and contaminants, ensuring the infant formula remains fresh and safe. The sealing process creates a hermetic seal. Gas flushing systems are standard, reducing residual oxygen in the can to minimal levels, which is critical for preserving nutritional value and preventing spoilage. (Source: Dairy Consultant) Cans are also robust and prevent physical damage during transit and handling.

Cons: The initial investment for a complete, high-quality can filling and sealing line is substantial. These lines are also less flexible in terms of quick changes to can size or format compared to some pouching solutions. The packaging material (metal cans) can also be more expensive and heavier than flexible packaging options.

Applications: This is the most traditional and widely accepted packaging format for infant formula globally. It's used by major brands for both domestic and export markets where product stability and a long shelf life (often up to two years or more) are paramount. These lines can handle various can formats and are designed for high-volume, automated production.

What Key Features and Considerations Are Crucial for Infant Formula Packaging Machines?

You understand that selecting the right *type* of machine is just the first step. For a product as sensitive as infant formula, overlooking specific design features or operational considerations can lead to catastrophic hygiene failures, inaccurate dosing, or constant production headaches. How can you ensure the machine you choose is truly fit for purpose, safeguarding both the product and your business?

From my perspective, when selecting any infant formula packaging machine, you must prioritize several crucial features: hygienic design (e.g., stainless steel, easy-to-clean surfaces, CIP/SIP compatibility where feasible), precision dosing systems (like servo-driven augers), gentle product handling, effective dust control, and capabilities for modified atmosphere packaging (MAP), especially for cans. Furthermore, robust seal integrity testing, traceability features, and sealless integration with other line equipment are vital.

Let's look closer at these:

· Hygienic Design: All product contact parts should be made from food-grade stainless steel. The machine should be designed for easy and thorough cleaning to prevent microbial contamination. Some advanced systems may offer Clean-in-Place (CIP) or Sterilize-in-Place (SIP) capabilities.

· Dust Control: Powdered infant formula can create dust, which is a hygiene concern and a potential explosion hazard. Effective dust collection systems are essential.

· Accuracy and Consistency: Servo-driven auger fillers provide high dosing accuracy. Integrated checkweighers can verify fill weights and reject out-of-spec packages.

· Modified Atmosphere Packaging (MAP): For cans and some pouches, gas flushing with nitrogen is critical to remove oxygen, extending shelf life and preserving nutrients. The oxygen level in the final package is a key quality control parameter. (Source: Dairy Consultant)

· Seal Integrity: Whether it's a can seal or a pouch seal, it must be perfect. Leak detection systems are important for quality assurance.

· Traceability: The ability to print batch codes, manufacturing dates, and other tracking information is crucial for recalls and supply chain management. Laser printers are often used.

· Automation and Integration: Modern machines feature PLC control systems with user-friendly HMIs. They should also integrate smoothly with upstream equipment (like powder mixers) and downstream equipment (like case packers and palletizers).

Summary of Main Types and Characteristics of Milk Powder Packaging Machines

| Type | Main Features | Advantages | Disadvantages | Applicable Scenarios |

| Vertical Form Filling and Sealing Machine(VFFS) | The bag is made from film, the milk powder is filled vertically, the seal is made, and then it is cut into individual packages. | The equipment has a compact structure and is suitable for various bag types (pillow type, back-sealing, three-side sealing, four-side sealing, with zippers, etc.). The investment is relatively low. | The speed is slower than that of the horizontal machine, and the shape of the packaging bag is simpler. | Small and medium-sized production lines, bagged milk powder, flavored milk powder, etc. |

| Horizontal Form Filling and Sealing Machine(HFFS) | Horizontal bag-making filling, suitable for complex bag shapes such as stand-up pouchs, zipper bags, and suction nozzle bags. | Fast speed, high packaging quality, suitable for complex packaging designs | The equipment is large in size, and the investment and maintenance costs are high. | Large-scale production requires milk powder products with diverse packaging forms. |

| Rotary Packaging Machine | Multi-position rotating worktable, continuous high-speed packaging | High production capacity, suitable for mass production, with high degree of automation | The equipment is complex and has high maintenance requirements. | Large dairy enterprises, packaging of canned and bottled milk powder |

| Spiral Metering Packaging Machine(Auger Filler) | Precisely measure the milk powder through a screw conveyor, and it is often used in conjunction with VFFS or canning lines. | Highly accurate measurement, suitable for various powder flow properties, and with high degree of automation. | Limited handling of viscous powders is required, and the screw components need regular maintenance. | Precise measurement is required for high-quality milk powder packaging, such as infant formula milk powder. |

| Volume Cup Metering Packaging Machine(Cup Filler) | By using the preset volume cup for measurement, it is suitable for granular or fluidized powder. | Fast speed, simple structure, easy maintenance | The measurement accuracy is lower than that of the spiral metering method, and it is difficult to handle viscous powders. | Granular milk powder and auxiliary material packaging, with relatively high output requirements but average precision requirements. |

| Vacuum Metering Packaging Machine(Vacuum Filler) | By using vacuum suction to collect the powder, it is suitable for lightweight, easily airborne or sticky powders. | Suitable for fine and easily clumped powders, reducing dust flying | The equipment has a high cost and is complex to maintain. | High-end infant formula milk powder and special formula milk powder require a highly clean environment. |

| Premade Pouch Packaging Machine | Using pre-made bags, automatic filling and sealing are achieved, suitable for various bag types. | Easy to change bags, suitable for multi-variety and small-batch production. | The cost of premade bags is high and their adaptability is limited. | Multiple product varieties and small batch production, requiring rapid switching of packaging specifications |

| Can Filling Machine | For filling and sealing of milk powder in rigid containers such as metal cans and plastic cans | Good sealing performance, extended shelf life, suitable for high-end milk powder products | The equipment is complex and the investment is high. It is suitable for large-scale production. | Infant formula milk powder, export high-end milk powder in cans |

Summary of Recommendations

| Type of Demand | Recommended Device Type | Key Considerations |

| Small batch size, multiple varieties | Pre-made bag machine, semi-automatic spiral metering machine | Flexibility, convenient bag replacement, investment cost |

| Medium production capacity | Vertical Form filling and sealing machine (VFFS) | The equipment is compact, easy to operate and adaptable to various bag types. |

| Large-scale and high-precision | Horizontal form filling and sealing machine (HFFS), rotary packaging machine | High speed, high automation, and complex packaging requirements |

| High-end infant formula milk powder | Spiral metering packaging machine, canning packaging machine | Highly accurate measurement, excellent sealing performance, and in compliance with GMP standards. |

Choosing the right infant formula packaging machine is a critical decision that impacts your product quality, operational efficiency, and brand reputation. I hope this overview has given you a clearer understanding of the types of machines available and the key factors to consider. Your specific production volume, desired packaging format, hygiene requirements, and budget will ultimately guide your choice.

If you have more questions or need help finding the best solution for your enterprise, please feel free to reach out. We are here to help you succeed.

Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: Milk Powder Filling Production Line;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to milk powder packaging line that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.How to Build an Efficient Canned Milk Powder Packaging Line?

2.How to Select the Right Infant Formula Packaging Equipment for Global Markets?

3.What Are Common Problems with Powder Filling Machines and How to Fix Them?