You might have noticed that the price range for potato chips lines is huge – from tens of thousands to several hundreds of thousands of dollars. This is because many factors influence the cost. Understanding these factors will help you figure out why one line is priced higher than another and how to get the best value for your budget. Here are the key factors that affect the cost of a potato chips frying production line:

· Production Capacity: This is one of the biggest drivers of cost. A small line that makes a few dozen kilograms of chips per hour is far less expensive than a large industrial line that cranks out hundreds of kilograms per hour. Higher capacity lines require larger machines (bigger fryers, more powerful motors, larger conveyors) and more automation to keep up with the volume, which increases the price. For example, a fully automatic line producing 100–150 kg/h might cost on the order of $50,000–$80,000, whereas a line producing 400–500 kg/h could easily cost $150,000–$250,000 or more. In short, the more chips you want to produce per hour, the more you’ll likely pay for the equipment.

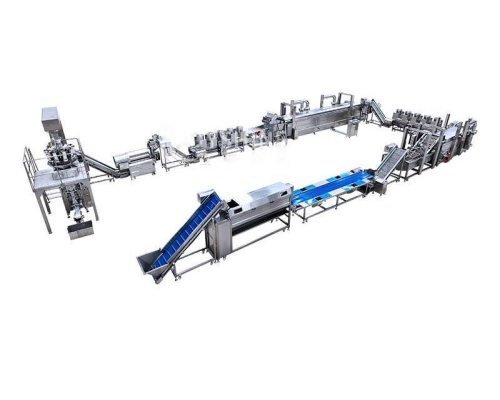

· Automation Level: Manual or semi-automatic lines are generally cheaper because they have fewer complex components and rely on human labor for some steps. Fully automatic lines come with sensors, control systems, and integrated conveyors that move product seamlessly from one machine to the next, which adds to the cost. However, automated lines reduce labor needs and can improve consistency. The degree of automation (from manual feeding to fully PLC-controlled) will significantly affect the price tag. For instance, a basic batch fryer setup might be affordable, but a continuous fryer with automatic oil filtration and a linked packaging system is a much larger investment.

· Equipment Quality and Brand: Just like any machinery, you can pay a premium for well-known brands or higher quality construction. Established manufacturers with a reputation for reliability often price their lines higher than lesser-known or generic brands. High-quality materials (like heavy-duty stainless steel construction, better insulation on fryers, etc.) and robust engineering can justify a higher cost. These lines might last longer or require less maintenance. On the other hand, some budget lines might cut costs by using thinner materials or simpler designs, which could lead to higher maintenance or shorter lifespan. It’s a trade-off between upfront cost and long-term durability.

· Included Features and Technology: The specific features of the line will influence cost. For example, a fryer with advanced oil management (continuous filtration, oil recycling, energy recovery systems) will cost more than a basic fryer. A line that includes a sophisticated optical sorter or metal detector will be pricier than one that doesn’t. Similarly, a packaging machine with advanced capabilities (high-speed operation, nitrogen flushing, automatic film change) adds cost. Additional features like CIP (clean-in-place) systems, touchscreen controls, or the ability to produce different products (like both chips and fries or multiple flavors) can all increase the price. Essentially, the more bells and whistles, the higher the cost.

· Customization and Layout: If you need a custom solution – for example, a line tailored to fit in a specific factory layout or to meet unique product requirements – you might incur extra engineering costs. Standard off-the-shelf lines are usually cheaper, whereas a customized line built to your specifications will likely cost more due to the design work and possibly non-standard components. Some manufacturers charge engineering fees for custom layouts or modifications. It’s best to discuss your needs early; sometimes a standard line can be adapted without huge cost, but significant custom changes will add to the budget.

· Shipping and Installation: Don’t forget that the price quoted might not include shipping to your location or installation. If you’re importing the line from another country, freight charges, customs duties, and taxes can add a substantial amount (often 10–20% or more of the equipment cost). Installation services – where technicians come to set up the line, connect utilities, and train your staff – usually come at an extra cost as well. Some suppliers offer a turnkey package (equipment + shipping + installation + training) for a higher upfront price, which might be convenient. Be sure to clarify whether the quoted price is ex-works (not including shipping) or delivered and installed.

· Supplier and Location: The cost can vary depending on where you buy the line. For instance, lines manufactured in China or other countries with lower production costs are often priced more competitively than those made in Western Europe or the U.S. This is why you might see Chinese-made lines in the $20k–$50k range for moderate capacities, whereas a European-made equivalent could be $100k+. That said, lower-cost suppliers might have different standards or require more support, so it’s not just about the sticker price. Also, local suppliers might charge more but include better after-sales service. It’s a balancing act between cost and the level of support and quality you need.

· Market Conditions and Currency: The cost of machinery can fluctuate with market conditions – for example, if the price of steel rises, equipment prices might go up. Exchange rates also play a role if you’re buying internationally. A weakening of your local currency could effectively increase the cost of an imported line. It’s wise to keep an eye on such factors if you’re planning a purchase in the future.

To summarize, capacity and automation are the two biggest factors in determining cost, but quality, features, and service also contribute. When evaluating quotes, break down what’s included. A slightly more expensive line that includes installation and has a good warranty might be a better deal than a cheaper one that leaves you on your own for setup and maintenance. Always consider the total cost of ownership – not just the purchase price, but also operating costs (energy, oil, maintenance) and the support you’ll get from the manufacturer. This holistic view will help you make a smart investment decision for your potato chips business.

Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: Fried-Potato-Chips-Production-Line; Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to potato chips production line that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.Introduction to the main equipment and functions of potato chip production line.

2.What are the methods and precautions for selecting a potato chips production line?

3.What is the maintenance cost of the potato chip production line?

4.How long does it take to replace key components in the potato chip production line?

5.What is the raw material loss rate in potato chip production?

6.What are the common causes of wastage in potato chip production?

7.How to do daily inspection of potato chips production line?