The Complete Guide to Customizing Fruit and Vegetable Cleaning & Packaging Lines: What Are the Key Considerations?

Fresh produce processors constantly face a pressing dilemma: How to balance processing efficiency with product quality while meeting strict food safety standards. Customized cleaning and packaging lines offer tailored solutions, but 43% of food manufacturers report challenges in proper system configuration.

Successful customization requires matching equipment capabilities with operational realities. Key considerations include verifying throughput requirements, analyzing product characteristics, optimizing workflow sequences, selecting durable components, and building in quality control checks. Partnering with experienced engineers through the design phase prevents 72% of common installation issues.

Custom production lines aren't just machines - they're strategic investments. Our 11 years experience serving global clients reveals five critical decision areas that determine your ROI. Let's explore each factor with real-world implementation examples.

1.How to Accurately Assess Needs vs. Production Scenarios?

When a Mexican avocado processor demanded 8-ton/hour capacity, our engineers first analyzed their actual workflow. The revelation? Their existing manual grading caused 40% throughput bottlenecks.Effective capacity planning combines current volumes with 3-year growth projections. Critical parameters include:

- Raw material input rates (kg/hr)

- Required sorting accuracy levels (%)

- Packaging format changes per shift

- Seasonal production fluctuations

Recent case studies show that plants using detailed requirement matrices reduce equipment over-specification costs by 28%. Our engineers conduct evaluations to map your facility's spatial constraints, utility interfaces, and staff skill levels.

2.What Defines Optimal Process Flow Design?

A Turkish tomato processor learned this hard truth: Their brilliant fermentation stage ruined the subsequent washing efficiency. We redesigned their line sequence, boosting yield by 18%.Standard cleaning-packaging sequences (pre-wash → brush → rinse → dry → sort → pack) require customization based on:

- Produce tenderness (spinach vs. potatoes)

- Contamination types (soil vs. pesticide)

- Microbial control requirements

- Final packaging moisture tolerance

Critical Modifications in Practice

1). Leafy Greens Path

Vortex pre-wash → Bubble massage → Drying

*Preserves cell structure while removing 99.3% sand particles*

2). Root Vegetables Path

High-pressure spray → Rotating brush → UV sterilization

*Maintains peel integrity with 3-log pathogen reduction*

3.How to Select Equipment with Maximum Reliability?

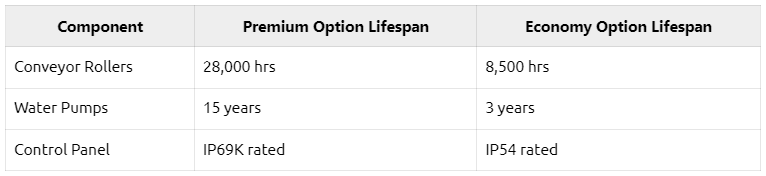

The core metrics go beyond price tags. When evaluating commercial washers, consider:- Wear Resistance: 3mm vs 5mm stainless steel housings

- Sanitation Design: CIP compatibility, drainage slopes

- Precision Control: ±1% speed regulation

- Component Brands: SKF bearings vs generic alternatives

Our clients' maintenance logs reveal:

Investing in food-grade polymers and marine-grade stainless steel reduces unscheduled downtime by 67%. Our technical team provides lifecycle cost comparisons to guide smart investment decisions.

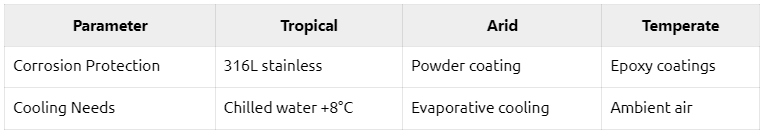

4.What Environmental Factors Impact System Configuration?

Energy consumption accounts for 34% of operational costs in produce processing. Our Egyptian client's line now recycles 92% process water through:- Steam condensation recovery

- Multi-stage filtration loops

- Rainwater harvesting integration

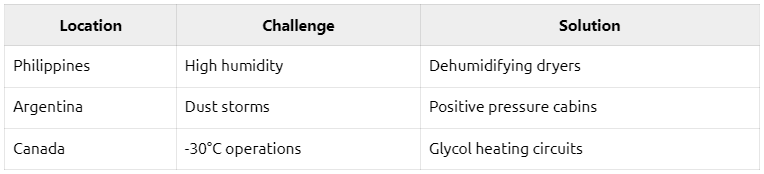

Climate adaptations we've implemented:

5.Why Should Quality Systems Be Integral to Design?

Our Australian customers achieve real-time monitoring through the Internet of Things:- Wash water pH/turbidity

- Brush roller RPM deviation

- Package seal strength

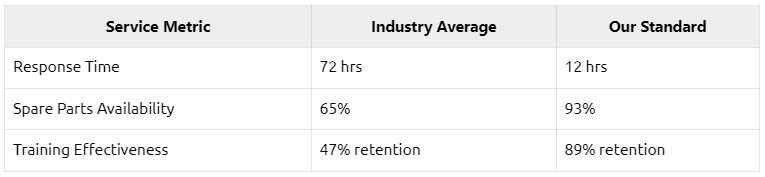

Automated alerts flag parameter drifts before defects occur. Post-installation support combines:

- Remote diagnostics (85% issues resolved online)

- Supply of spare parts

- Operator certification programs

We maintain:

6.Conclusion

Customization success lies in marrying technical specifications with operational intelligence. From precise capacity calculations to climate-smart engineering, every detail impacts your bottom line. Actual cases show that scientifically customized production lines can reduce the overall operating costs by 18-25%.Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: Fruit and vegetable washing, waxing, drying and sorting production line; Oranges cleaning, drying, waxing and sorting production line; Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to the bubble washing machine that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.What is the bubble cleaner?

2.How does the bubble cleaner work?

3.What are the common faults of the bubble cleaning machine?