Both horizontal and vertical packaging machines are indispensable and important roles in the production process of modern packaging industry. They silently interpret their own packaging art on the fast-paced production line, bringing convenience and beauty to our daily lives. So, when choosing a packaging machine, is it better to choose a horizontal packaging machine? Is it more cost-effective to choose a vertical packaging machine? Today, let's discuss together.

Analysis of advantages and disadvantages

| Content | Advantage | Insufficient |

| Horizontal packaging machine |

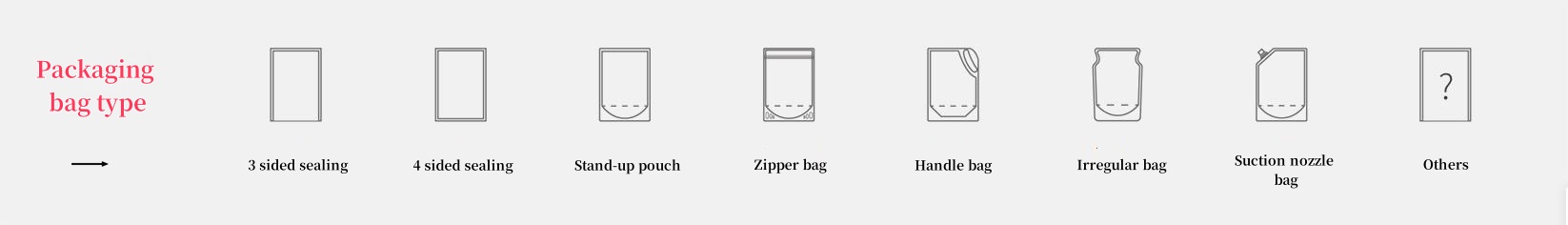

1.Widely applicable products: It can meet various product packaging needs, especially suitable for flat or long shaped products such as cookies, bread, candies, etc., as it provides a large space in the width direction. 2.High speed production capacity: Due to moving in a straight line, it usually achieves higher packaging speeds and is suitable for large-scale production. 3.Small footprint: Compared to height, the flat layout design occupies less ground area. 4.Diverse filling options: By matching different measuring devices according to different materials, fully automatic packaging of products such as solids, liquids, particles, powders, blocks, soft cans, toys, hardware, etc. can be achieved. 5.Diversified packaging: Provides a variety of bag designs, such as self-supporting bags, zipper bags, four sided sealed bags, suction nozzle bags, special-shaped bags, etc., which cannot be achieved by vertical packaging machines. |

1.High initial investment: the complex design and high-end technology make its cost higher than that of a vertical packaging machine. 2.Product changes require adjustments: When converting product lines, it may be necessary to reconfigure device parameters or even replace certain components. |

| Vertical packaging machine |

1.Vertical operation saves space: Especially suitable for situations where workshop space is limited, vertical stacking reduces the footprint. 2.Economically efficient: Generally lower cost, more attractive to small businesses. 3.Quickly switch products: Easier to adjust to accommodate different sizes of packaging, especially when changing packaging sizes. 4.Vertical filling: Suitable for granular and powdery items, it can more effectively fill the packaging and reduce gaps. 5.Easy to operate: Usually designed to be intuitive, easy to operate and maintain. |

1.Speed limit: Compared to horizontal packaging machines, their packaging speed is usually lower. 2.Product limitations: For long or large products, a vertical packaging machine may not be the best choice. 3.Single packaging form: The shape of the packaging bag is relatively single, mostly with back sealing or three side sealing, which cannot meet personalized needs. |

Specific content comparison

1.Design direction:- Horizontal packaging machine: The film is formed, filled and sealed in the horizontal direction, because it can provide more space in the horizontal direction, suitable for the packaging of long, flat or irregular shaped products.

- Vertical packaging machine: film molding, filling and sealing along the vertical axis, suitable for the packaging of particles, powders, liquids and other free-flowing materials.

2.Packaging speed

- Horizontal packaging machines usually have faster speeds and are particularly suitable for high-speed packaging operations in large-scale production environments.

- The packaging speed of the vertical packaging machine is relatively slow, but it still maintains high efficiency for small and medium-sized batch production.

3.Land occupation space

- The horizontal packaging machine occupies a wide area of the ground, but due to its horizontal deployment, it may have lower height requirements.

- Vertical packaging machines have a relatively compact footprint and are more suitable for factory environments with limited space. Their height will be higher than that of horizontal machines.

4.Packaging Products

- Horizontal packaging machines are widely used for long and flat products in food and daily chemical products, such as chocolate bars, toothbrushes, syringes, toothpaste, tableware, etc.(How to pack sanitary tableware)

- The vertical packaging machine is suitable for various bulk materials, such as snacks, seasonings, chemicals and other granular, powdered or liquid products.

5.Packaging form

- Horizontal packaging can meet the personalized packaging form requirements, such as self-supporting bags, zipper bags, four sided sealed bags, suction nozzle bags, shaped bags, etc., which can meet the diverse packaging design of high-end products and provide more choices for enterprises to increase product market share.(Special shaped bag horizontal packaging machine)

- The packaging form of vertical packaging machines is relatively simple, commonly including back sealing and three side sealing.

6.Usability and flexibility

- The horizontal packaging machine may require more adjustment time and tools when changing the product packaging form and size, but its extensive packaging styles and high degree of automation improve production efficiency, and overall operation is still convenient.

- The vertical packaging machine has a relatively simple and fast adjustment for product variety changes, making it suitable for production lines with strong product diversity.

7.Investment cost and maintenance

- Horizontal packaging machines may have higher initial investment costs due to their more complex mechanical structure and high-speed functionality, but in the long run, they can improve productivity.

- Vertical packaging machines have relatively low initial investment and maintenance costs, making them more suitable for small businesses with limited budgets.

Therefore, for enterprises with larger production scale, higher production speed requirements, more product categories, higher packaging appearance requirements, and sufficient budget, horizontal packaging machine is the best choice; On the contrary, you can choose a vertical packaging machine.

Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: https://www.hnunmachinery.com/Automatic-Packing-Machine/Automatic-Horizontal-Packaging-Machine/;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to the Horizontal packaging machine that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.What is the horizontal bag making packer?

2.What is a premade bag horizontal packaging machine?

3.What are the common faults of the roll film horizontal packaging machine?

4.How to choose an excellent roll film horizontal packaging machine?

5.What factors should be considered when purchasing a roll film stand up pouch packaging machine?

6.How to choose between roll film packaging machine and premade bag packaging machine?