How Can Aseptic Filling Revolutionize Your Ice Cream Production?

Table of Contents

· Why is Food Safety So Critical in Ice Cream Manufacturing?

· What are the Key Benefits of Using Aseptic Technology for Ice Cream?

· What Common Challenges Does Aseptic Filling Solve in Ice Cream Production?

· How Can You Integrate Aseptic Systems into Your Production Line?

· Conclusion: The Future is Aseptic

Are you tired of seeing your profits melt away due to the high costs of cold chain logistics for your ice cream products? You invest so much in creating the perfect flavor and texture, only to face the constant pressure of short shelf lives, spoilage risks, and limited distribution reach. This dependency on refrigeration chains not only inflates your operational expenses but also restricts your market to areas with reliable cold storage, leaving vast potential untapped.

Aseptic filling technology is the solution that allows you to produce shelf-stable ice cream mixes and dairy products that do not require refrigeration for months. This process involves sterilizing the product and the package separately and then combining them in a completely sterile environment. By doing this, you can break free from the cold chain, dramatically extend your product's shelf life, and expand your market reach globally, all while ensuring top-notch product safety and quality.

What Exactly is Aseptic Filling and How Does It Work?

You've probably heard the term "aseptic" but might feel it sounds overly complex or expensive. Many business owners worry that adopting such advanced technology means a complete overhaul of their factory and a steep learning curve for their staff. This hesitation can make you stick with traditional methods, even if they are less efficient and more costly in the long run.Aseptic filling is a manufacturing process where a commercially sterile product, like an ice cream mix, is filled into a pre-sterilized container within a sterile environment. The core principle is to prevent any microorganisms from contaminating the product during and after packaging. This is different from traditional canning, where the food is sterilized inside the container. Here, the product (often through Ultra-High Temperature or UHT treatment) and the packaging are sterilized separately before they meet, ensuring a longer shelf life without preservatives or refrigeration, as defined by the United States Department of Agriculture (USDA).

The process starts with making the product commercially sterile. For liquid dairy products like ice cream mix, this is often achieved through UHT treatment. This method heats the product to a very high temperature (135-150°C) for just a few seconds. This quick process effectively kills harmful bacteria and spores with minimal impact on the product's taste and nutritional value. After the UHT treatment, the product is rapidly cooled and held in sterile aseptic storage tanks before filling. At the same time, the packaging materials, such as cartons or pouches, are sterilized, often using methods like hydrogen peroxide and UV light. Finally, the sterile product is filled into the sterile packages and sealed in a hygienic, controlled environment, creating a final product that is safe and shelf-stable.

A modern UHT sterilization system with an intricate network of pipes and controls for processing dairy products

Why is Food Safety So Critical in Ice Cream Manufacturing?

As a food manufacturer, the thought of a product recall is a nightmare. A single contamination incident can lead to widespread illness, devastating financial losses, and irreparable damage to your brand's reputation. With global distribution chains, a contaminated product can travel across countries, potentially affecting thousands of consumers and creating a public health crisis, a risk highlighted by the World Health Organization.Maintaining the highest hygiene standards is non-negotiable in ice cream production to prevent foodborne illnesses and ensure consumer trust. This involves implementing strict protocols at every stage, from handling raw materials to final packaging. Key practices include rigorous temperature control, regular pest control, and comprehensive personal hygiene training for all food handlers. Adhering to a system like Hazard Analysis and Critical Control Points (HACCP) is essential for systematically identifying and controlling potential hazards.

The UK's Food Standards Agency emphasizes the "4Cs" of food hygiene: Cross-contamination, Cleaning, Chilling, and Cooking (or processing). Aseptic technology directly addresses these concerns. The closed, sterile environment of an aseptic filling line drastically reduces the risk of cross-contamination. The UHT process ensures the product is free of harmful microbes, and the sterile packaging protects it until it reaches the consumer. Furthermore, automated Clean-in-Place (CIP) systems ensure that all equipment is thoroughly sanitized between production runs, maintaining a consistently high level of hygiene with minimal manual intervention.

A sophisticated Clean-in-Place (CIP) system, essential for maintaining hygiene in food processing plants

What are the Key Benefits of Using Aseptic Technology for Ice Cream?

Are you constantly battling the limitations of a short shelf life for your dairy products? The need for constant refrigeration not only drives up your energy bills but also creates a mountain of logistical challenges and food waste. This makes it incredibly difficult to plan production efficiently, expand into new markets, or even manage seasonal demand without risking spoilage and lost revenue.The primary benefits of aseptic technology are a dramatically extended shelf life without refrigeration, superior preservation of product quality, and significant cost savings across the supply chain. This technology transforms how you produce and distribute products like ice cream mix, milk, and cream. It allows for centralized production while enabling distribution to distant or remote markets that may lack a consistent cold chain, ultimately reducing waste and boosting profitability.

Extended Shelf Life Without Refrigeration

The most game-changing benefit is the ability to create shelf-stable products. Aseptic packaging can extend the shelf life of dairy products like ice cream mix from a few weeks to 6 to 12 months at ambient temperatures. This is possible because the combination of UHT processing and sterile packaging creates a powerful barrier against microorganisms, light, and oxygen. This stability allows you to produce in longer, more efficient runs and simplifies inventory management, as products can be stored and shipped without the urgency and cost of refrigeration.Preserved Quality and Flavor

You might think that high-heat treatment would degrade the product's quality, but the opposite is often true compared to other preservation methods. Because UHT processing is so rapid, it has a minimal thermal impact on the product. This helps preserve the natural flavor, color, and nutritional value of the ice cream mix. Unlike traditional canning, which can lead to cooked flavors, aseptic processing maintains a fresher taste. Advanced systems like Tetra Pak's direct UHT technology are specifically designed for heat-sensitive products to ensure microorganisms are eliminated with the least possible effect on taste and color.

An example of a shelf-stable, pasteurized ice cream mix in an aseptic carton, ready for distribution

Reduced Costs and Environmental Impact

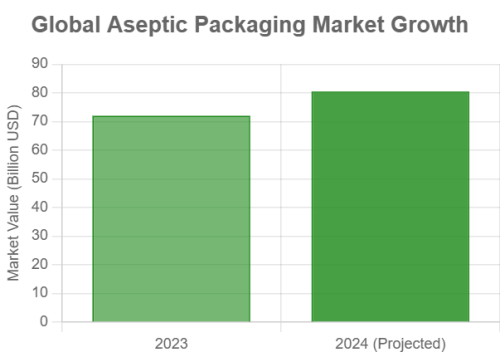

By eliminating the need for a refrigerated supply chain, you can achieve massive cost savings. Energy consumption from cold storage and transportation plummets. This not only lowers your operational expenses but also reduces your carbon footprint. Furthermore, aseptic packaging materials like cartons are often lightweight and made from renewable resources, offering a more sustainable alternative to heavier packaging. Life Cycle Analysis (LCA) studies have shown that aseptic systems generally have a lower environmental impact compared to hot-fill and other traditional methods. The growing market, which surpassed $72 billion in 2023, reflects the industry's confidence in these benefits.

Data Source: Fortune Business Insights, via Dairy Foods Magazine

What Common Challenges Does Aseptic Filling Solve in Ice Cream Production?

Every ice cream maker knows the frustration of product defects. Issues like an icy texture, flavor loss, or inconsistent body can ruin a batch and disappoint customers. These problems often stem from improper processing, temperature fluctuations during storage, or microbial activity. You work hard to perfect your recipe, but these defects can undermine all your efforts and lead to a perception of low quality.Aseptic processing and packaging directly address the root causes of many common ice cream defects by ensuring microbiological stability and protecting the product from external factors. By creating a commercially sterile product and sealing it in a protective package, this technology helps maintain the intended flavor, body, and texture from the factory to the consumer, ensuring a consistent and high-quality experience every time.

For example, a coarse or icy texture in ice cream is often caused by the growth of large ice crystals, which can happen with temperature fluctuations during storage and distribution. A shelf-stable aseptic ice cream mix eliminates this problem for the B2B supply chain, as it's stored at ambient temperature. The final freezing happens just before consumption, ensuring a smooth texture. Flavor defects, such as cooked or stale tastes, are minimized because the UHT process is extremely short. Furthermore, the aseptic package, often containing layers of paper, polyethylene, and aluminum, provides an excellent barrier against oxygen and light, preventing oxidation and flavor degradation that can occur over time .

How Can You Integrate Aseptic Systems into Your Production Line?

The idea of integrating a whole new system into your existing production line can seem daunting. You might imagine long periods of downtime, high initial investment costs, and the need for specialized training that you can't afford. This perception often stops companies from exploring technologies that could give them a significant competitive edge.Integrating an aseptic system is more flexible and accessible than ever before, with modern equipment designed for versatility, efficiency, and easier operation. Suppliers offer modular solutions that can be tailored to your specific needs, and options like contracting with a co-packer allow you to test the market without a large upfront investment. This makes it possible to adopt aseptic technology in a phased, manageable way.

Many processors start by producing an aseptic ice cream mix. This allows them to supply a high-quality, shelf-stable base to a wide range of customers, such as restaurants and smaller ice cream shops, who can then freeze it on-site. This is a common practice in the foodservice industry, as noted in a report from Kansas State University. As your business grows, you can invest in a complete line. Modern aseptic filling lines from providers like Union Machinery are designed for flexibility, allowing quick changeovers between different products and package formats, which minimizes downtime and maximizes efficiency.

Key Equipment in an Aseptic Line

A typical aseptic line for ice cream mix includes several key components. It starts with mix preparation equipment, followed by a UHT processing unit for sterilization. After sterilization, the product moves to an aseptic storage tank, which acts as a buffer before filling. The heart of the system is the aseptic filling machine, which sterilizes the packaging, fills it with the sterile product, and seals it hermetically. Leading suppliers like Union Machinery offer integrated solutions that cover this entire process, ensuring all components work together seamlessly.The Role of HACCP and Quality Control

Integrating an aseptic system requires a robust quality control framework. A Hazard Analysis and Critical Control Points (HACCP) plan is essential. For ice cream production, critical control points often include raw material reception, the sterilization step (UHT), and the integrity of the aseptic filling and sealing process. A study on applying HACCP in ice cream production identified seven critical control points, including sterilization and the CIP system. Continuous monitoring of these points is vital to ensure the commercial sterility and safety of the final product. Implementing a strong HACCP program is not just a regulatory requirement; it's a tool for continuous improvement and building confidence with your customers.Conclusion: The Future is Aseptic

In a competitive global market, efficiency, safety, and innovation are key to success. Aseptic filling technology is not just an incremental improvement; it's a transformative leap for the ice cream and dairy industry. It offers a clear path to overcoming the traditional challenges of spoilage, high distribution costs, and limited market access.By embracing this technology, you can produce higher quality, safer, and more convenient products for your customers. You can expand your business into new territories, reduce your environmental footprint, and build a more resilient and profitable operation. The future of ice cream production is shelf-stable, and aseptic filling is the key to unlocking that future.

Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: Aseptic-Carton-filling-machine;More video information see view:200ml-aseptic-carton-filling-machine ; Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to aseptic carton filling production that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.What is the aseptic filling machine?

2.How to ensure the quality and safety of aseptic carton filling products?

3.What are the common forms of aseptic carton packaging?

4.What are the main equipment of aseptic carton filling line?

5.Aseptic carton filling common problems and solutions.

6.How to ensure the aseptic effect of aseptic carton filling?

7.What should be noted when buying a aseptic carton filling machine?

8.What are the benefits of using a sterile carton filling machine?

9.How can aseptic carton filling machines help enterprises improve production efficiency?

10.What is the maintenance cost of a aseptic carton filling machine?

11.How to judge the quality of aseptic carton filling machine?