Project Background

In February 2024, a food processing company in Yemen, aiming to enhance the added value of mangoes and expand export markets, ordered an automated mango cleaning, drying, waxing, and sorting processing line from our company. This project covers the entire post-harvest processing workflow for mangoes, facilitating the client's industrial upgrading from "primary cultivation" to "standardized products."Customer Core Pain Points

- High Loss Rate of Mangoes: Traditional manual cleaning and sorting result in over 30% of fresh fruits being damaged or moldy, affecting product value and storage life.

- Low Processing Efficiency: The daily processing capacity is less than 5 tons, which cannot meet the demand of export orders;

- Difficulties in Quality Standardization: lack of professional sorting equipment, uneven fruit size and color, weak competitiveness in the international market.

- High Adaptability Requirements for Equipment: The local climate environment and mango varieties in Yemen have special characteristics, requiring equipment with strong stability and customized processing capabilities.

Customized solutions

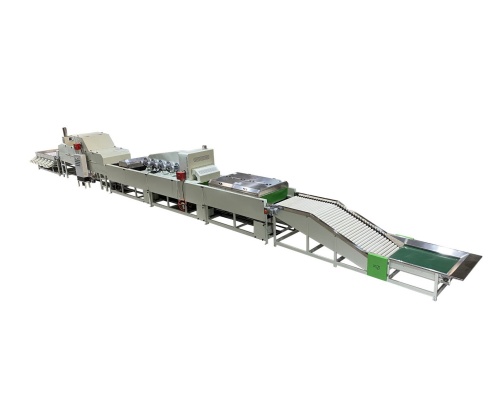

In response to the characteristics of tropical fruits and customer production capacity requirements, we provide a modular production line that integrates "washing - air drying - waxing - sorting":- Efficient Cleaning System: using bubble surfing and spray dual effect cleaning to remove sediment and pesticide residues on the fruit surface, with a cleaning rate of 99%;

- Low Temperature Air Drying Technology: 45 ℃ constant temperature air duct, quickly drying the moisture on the fruit surface to avoid mold growth after waxing;

- Food Grade Waxing Process: evenly spray edible grade fruit wax to extend the shelf life to 21 days (traditional process only takes 7 days);

- Intelligent Sorting Equipment: Through the visual system and weighing sorting system, defective products are automatically removed and graded by weight (50-500g) and color, with a sorting accuracy of ± 2g, greatly improving product grading standardization and added value.

Project Achievements

- Capacity Improvement: The single line processing capacity has reached 2-3 tons/hour, with an efficiency increase of over 300% compared to the old mode;

- Quality Upgrade: The product yield (A-grade fruit) has been increased to over 85%, the loss rate has been reduced to below 5%, and the appearance and shelf life have reached export standards.

- Decreased Loss Rate: The loss rate in the processing stage has decreased from 30% to below 5%, saving over $120000 in annual costs;

- Market Premium: Standardized products have successfully entered the Middle East and North Africa market, with a 25% increase in terminal prices and an annual revenue growth of approximately $800000 for customers.

Customer Review:

"This production line has enabled our mangoes to make the transition from 'farm price' to 'export price'. It not only alleviated our concerns about production capacity, but also its intelligent sorting capabilities have significantly enhanced the profit margin of our products. The stability and after-sales service of Union Machinery's equipment exceeded our expectations!"

-- Yemen customer project manager

Why Choose Union Machinery?

Industry Specialization: Over a decade dedicated to the R&D and manufacturing of food packaging machinery, deeply understanding the processing characteristics of fruits and vegetables products.Customization Capability: Can provide personalized solutions based on customers' specific products, packaging dimensions, and production capacity requirements.

International Certification: The equipment complies with international standards such as CE and ISO, and has been exported to 50+ countries and regions worldwide.

Full Cycle Service: Full support from demand analysis, scheme design, installation and commissioning to after-sales training throughout the process.

Cost-Performance Advantage: Compared to similar equipment from Europe, offers the same performance but with more competitive pricing options.

Act Now: Embark on Your Automation Transformation Journey

If you face production bottlenecks, high energy costs, or equipment compatibility challenges, reach out to Union Machinery!

· Free production line diagnostics

· Customized solution design

· Capacity simulation & ROI analysis

· Case studies of successful practices in the same industry

Union Machinery, A global leader in food packaging, committed to enhancing customer competitiveness through innovative machinery. Complete export certification and 100% on-time project delivery rate.

Union Machinery —— Make every mango a quality brand!