Chain bucket granule packing machine with strong expansion ability, cooperate with even bag device and air charging system to fulfill different special request....Read more

VIDEO

Introduction

This rotary type powder packing machine is the typical automatic bag feeding packing machine; it is suitable for many kinds of materials and different packaging bag. It is easy to adjust and operate and to change the packing specification. The rotary bag-give packing machine is equipped with automatic checking and safety monitoring function. It can lower the consumption rate of wrapping material and keep the sealing effect and bag shape. The whole machine is made of Stainless Steel which is hygienic and safety.Application:

This chain bucket granule packing machine is suitable for packing fragile material: potato chip, crispy rice, apple flakes, fruit jelly, hardware, frozen food etc.Loosen food: potato chips packing, apple chips packing, puffing food packing, etc.

Small hardware: nut packing, screw packing, small metal piece packing, belt buckle packing.etc.

Specification:

| Model | YY-1000A | YY-500A |

| Bag length | 100-280mm | 50-180mm |

| Bag width | 100-190mm | 50-140mm |

| Packing speed | 20-40bag/min | 20-60bag/min |

| Packing range | 100-1000ml | 10-180ml |

| Power | 2KW/220V/50Hz | 1.5KW/220V/50Hz |

| Total weight | 350kg | 300kg |

| Dimension | 1500*900*2000mm | 1000*800*1900mm |

Features:

1. Micro computer with English button of this automatic granule packing machine, easy to operate.2. Buffer design equipped with this granule packaging machines, design for big volume.

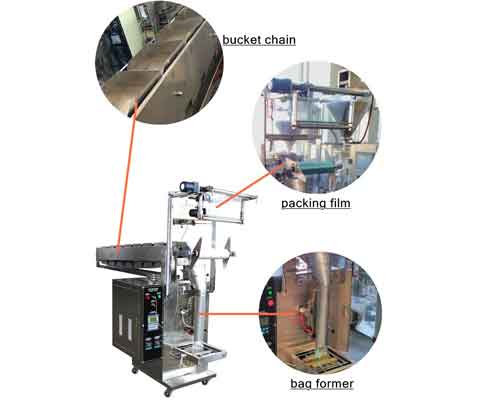

3. Granule packing machine with bucket chain elevator, which can conveyor the food into bag forma for finally sealing.

4. This Auto granule package machine could pack the M shape bag, which is very popular in the market now.

5. The process of bag making, measuring, filling, sealing, cutting, and counting can be done automatically.

6. The part where is contact to the material is made of stainless steel. Fully stainless steel cover is available.

7. Inverter and power switch are all imported with advanced technology.

8. Optional languages screen display, easy and simple operation.

9. Bag-making with precise technology enables the error less than ±o.5um.

10. High-sensitivity photoelectric color tracing and digital input of cutting position get more accuracy.

11. Intelligent temperature controller and excellent heat balance make all kinds of packaging materials possible with good performance, low noise, clear cutting pattern and strong seal ability.

12. Packaging speed and length of bags can be set to some extent without parts changing.

13. Equipped with screw rod device enables the changing of packing volume anytime; Loss reducing and productivity improving.

14. Alarming function for specific output; automatic display of packaging speed.

15. Optional coding device for lot number and date printing.

16. Flat cutting, pattern cutting, linking cutting can be realized by changing the tools; easy operation with smooth bags.

Packing material:

Several kinds of heat-seal lamination, such as PET/Plated AL/PE PET/PE, Nylon, etc.Optional fittings

- 1. Air compressor

- 2. Finished product conveyor

- 3. Check weigher

- 4. Meter detector

- 5. Nitrogen-making machine

- Optional function devices

- 1. Hole punch device

- 2. Tear notch device

- 3. Linking bag control device

- 4. Air exhaust device

- 5. Nitrogen inflation device

- 6. Liquid pump device for packing liquid material